HOME » Sustainability » To continue to be an earth-friendly company

To continue to be an earth-friendly company

We are aware that using a substantial amount of energy and fuel is crucial for our two main businesses (tableware and industrial devices). We have set up and implemented an environmental management program that aims to limit the impact of our corporate activities on the environment. Furthermore, we have been pursuing various ways to realize a circular economy from the perspective of the 3Rs (reduce, reuse, recycle), which is considered a challenging task in the tableware industry.

Manufacturing process

We have two factories for our tableware business (Japan and Indonesia) and one for our industrial devices business (Japan). Each factory is implementing environmental management strategies in pursuit of productivity and efficiency in consideration of the global environment, and is transitioning to a system of producing “only what is needed and in the quantity needed” through DX (digital transformation) and an improved inventory management structure. We are constantly seeking to minimize energy consumption and CO2 emissions, as well as to reduce and recycle various types of waste.

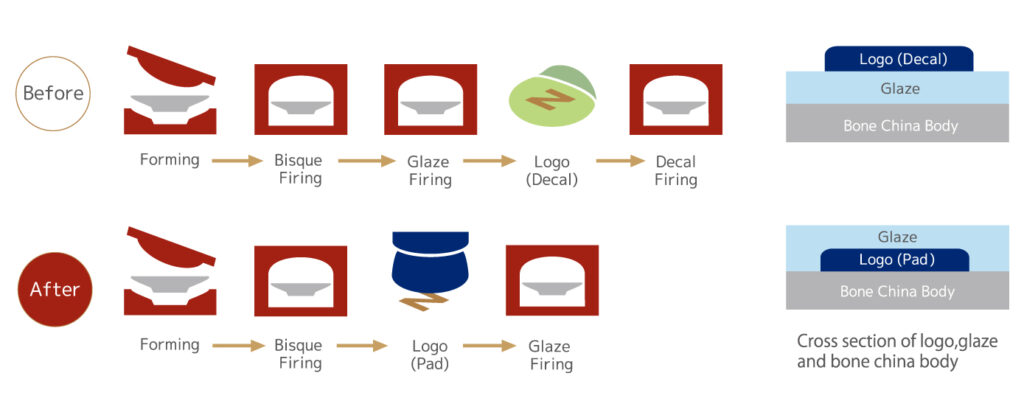

Improvement of Firing Process

Plain white bone china without patterns used to require three rounds of firing, but now most of these products are only fired twice, which contributes to a significant reduction in CO2 emissions. This also leads to improved durability of the product itself, as the brand logo is applied before glaze coating.

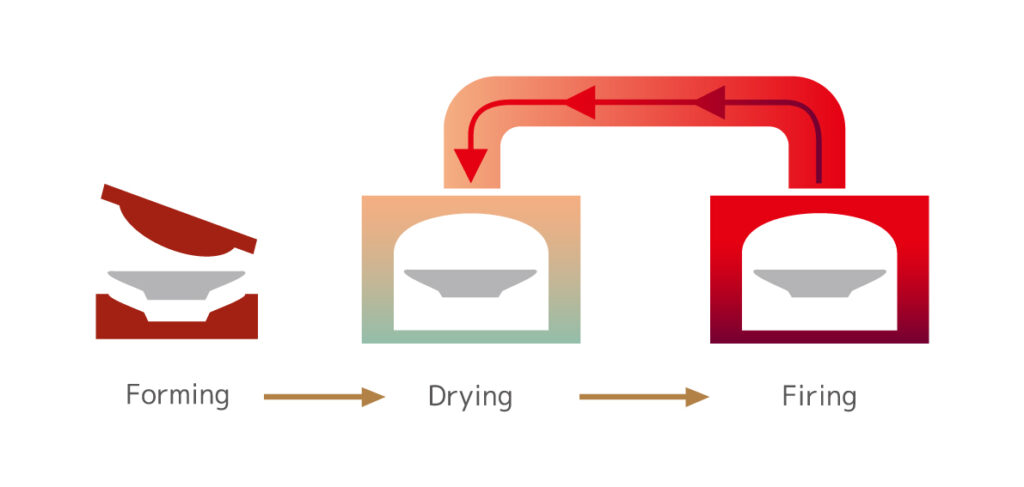

Waste Heat Recycling

In order to reduce CO2 emissions, we recycle waste heat from the firing furnace and use it as a heat source instead of using gas as a heat source for the drying room.

Reusing of Raw Materials

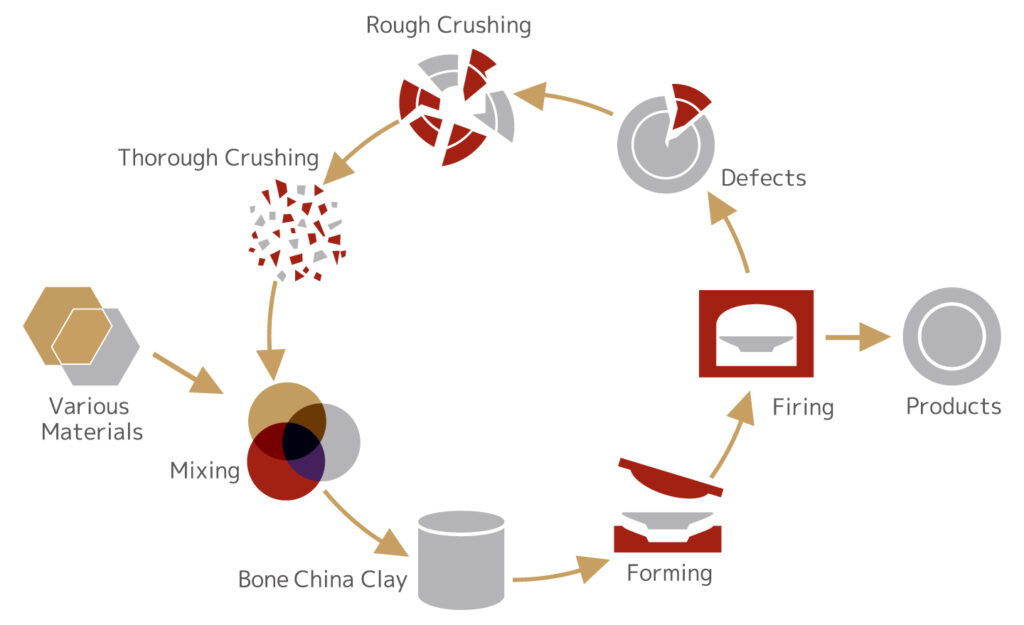

About 9% of the raw materials used in NARUMI’s bone-china products are recycled materials, such as defective products generated in the manufacturing process. The defective products are crushed and returned to a raw state to be reborn as part of the raw materials for new products.

In addition, about 30% of the fresh raw material itself comes from a recycled material: calcium phosphate is a by-product of gelatin making, recycled as a raw material of chinaware.

We are striving to increase the ratio of recycled materials further by improving the process of recycling defective products and exploring other recycled materials that can replace existing materials.

Carbon Pass certified products

Some of our bone china products have been granted a “carbon pass” to offset the amount of CO2 emitted from the procurement of raw materials, all manufacturing processes, and even transportation to the store. The pass is a ticket that offsets the CO2 emitted by individuals and companies against emission reduction projects—for example, wind power generation and other clean energy projects in emerging countries. The tickets purchased by NARUMI are traded internationally through the Japanese government and used to meet Japan’s CO2 reduction targets, set under the Kyoto Protocol.

The Floral Paradise collection was granted a carbon pass in 2009 and continues to hold it. The collection uses completely lead-free color pigments to create vivid colors, making the design friendly to both the earth and people.